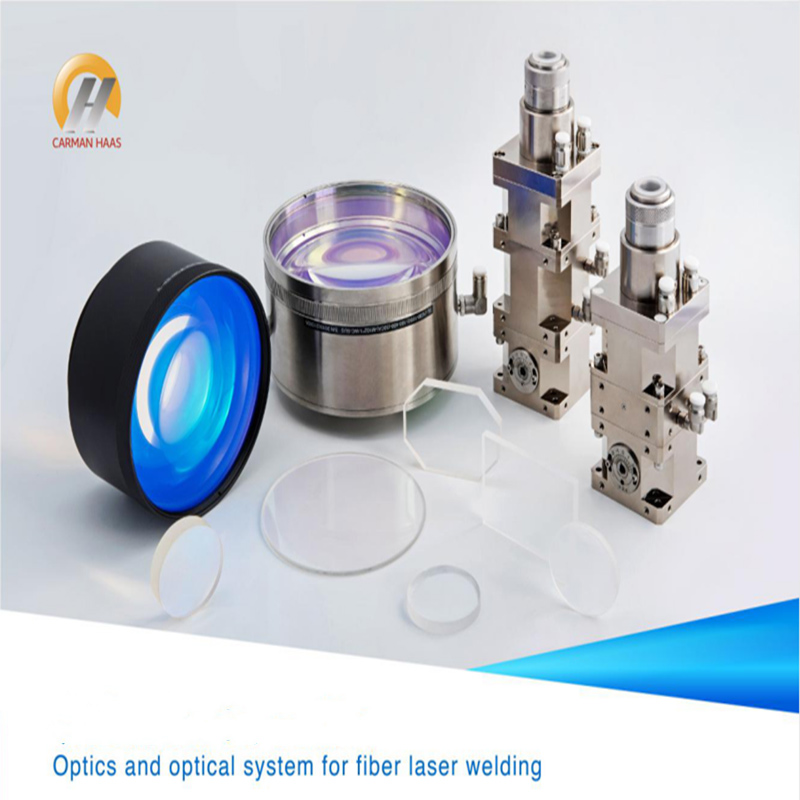

Optical module means a single function module in an optical system, including lenses and related mechanical components or simple electrical modules. According to customer needs, we can customize optics for various functions, including collimation, beam expansion, focusing, shaping, zooming, scanning and splitting, etc.

For different application, QBH module could shaping of the light source (divergence becomes parallel or small spot becomes larger), combined with beam combiner module, realizes the beam combining and splitting of the laser and monitoring light, and can realize the beam combining and splitting of the laser in the optical band.

1. Professional Optical and Structural R&D Team;

2. No stray light, diffraction limit design;

3. Wide range of application bands: 0.26um-12um;

4. Dual testing and calibration of optics and applications to ensure design and application consistency.

(1)for Laser welding system

|

Part Description |

Focal Length (mm) |

Clear Aperture (mm) |

NA |

Coating |

|

CL2-(900-1090)-30-F60-QBH-A-WC |

60 |

28 |

0.22 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F100-QBH-A-WC |

100 |

28 |

0.13 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F125-QBH-A-WC |

125 |

28 |

0.1 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F100-QBH-A-WC |

100 |

34 |

0.16 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F125-QBH-A-WC |

125 |

34 |

0.13 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F135-QBH-A-WC |

135 |

34 |

0.12 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F150-QBH-A-WC |

150 |

34 |

0.11 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F200-QBH-A-WC |

200 |

34 |

0.08 |

AR/AR@1030-1090nm |

(2)for 3D Printer

|

Part Description |

Focal Length (mm) |

Clear Aperture (mm) |

NA |

Coating |

|

CL2-(1030-1090)-25-F50-QBH-A-WC |

50 |

23 |

0.15 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F60-QBH-A-WC |

60 |

28 |

0.22 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F75-QBH-A-WC |

75 |

28 |

0.17 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F100-QBH-A-WC |

100 |

28 |

0.13 |

AR/AR@1030-1090nm |

(3)for Laser cleaning system

|

Part Description |

Focal Length (mm) |

Clear Aperture (mm) |

NA |

Coating |

|

CL2-(1030-1090)-30-F60-QBH-A-WC |

60 |

28 |

0.22 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F75-QBH-A-WC |

75 |

28 |

0.17 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F100-QBH-A-WC |

100 |

28 |

0.13 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F125-QBH-A-WC |

125 |

28 |

0.1 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F150-QBH-A-WC |

150 |

28 |

0.09 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F75-QBH-A-WC |

75 |

34 |

0.22 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F100-QBH-A-WC |

100 |

34 |

0.16 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F125-QBH-A-WC |

125 |

34 |

0.13 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F135-QBH-A-WC |

135 |

34 |

0.12 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F150-QBH-A-WC |

150 |

34 |

0.11 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-38-F200-QBH-A-WC |

200 |

34 |

0.08 |

AR/AR@1030-1090nm |

Note. If you need customized design, please contact to our sales.