CARMAN HAAS has a professional and experienced laser optics R&D and technical team with practical industrial laser application experience. The company actively deploys independently developed laser optical systems (including laser welding systems and laser cleaning systems) in the field of new energy vehicles, mainly focusing on laser applications of power battery, hairpin motor, IGBT and laminated core on New Energy Vehicles (NEV).

In the hairpin motor technique, a compressed air gun shoots preformed rectangles of copper wire (similar to hairpins) into slots on the edge of the motor. For each stator, between 160 and 220 hairpins have to be processed within no more than 60 to 120 seconds. After this, the wires are intertwined and welded. Extreme precision is required to preserve the electrical conductivity of the hairpins.

Laser scanners are often used prior to this processing step. For example, hairpins from particularly electrically and thermally conductive copper wire is often stripped from the coating layer and cleaned by laser beam. This produces a pure copper compound without any interfering influences from foreign particles, which can easily withstand voltages of 800 V. However, copper as a material, despite its many benefits for electromobility, also presents some drawbacks.

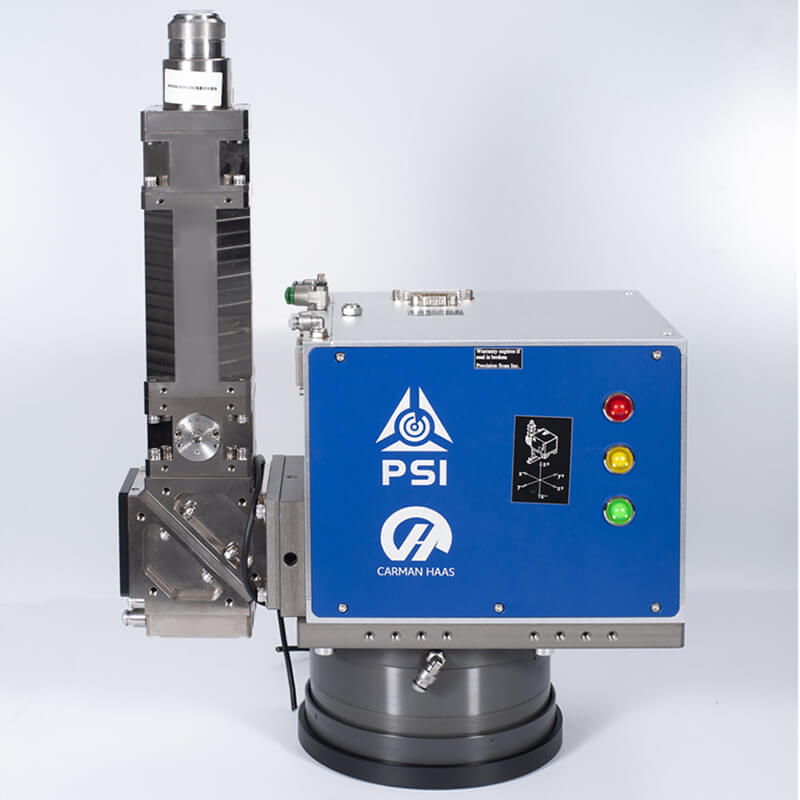

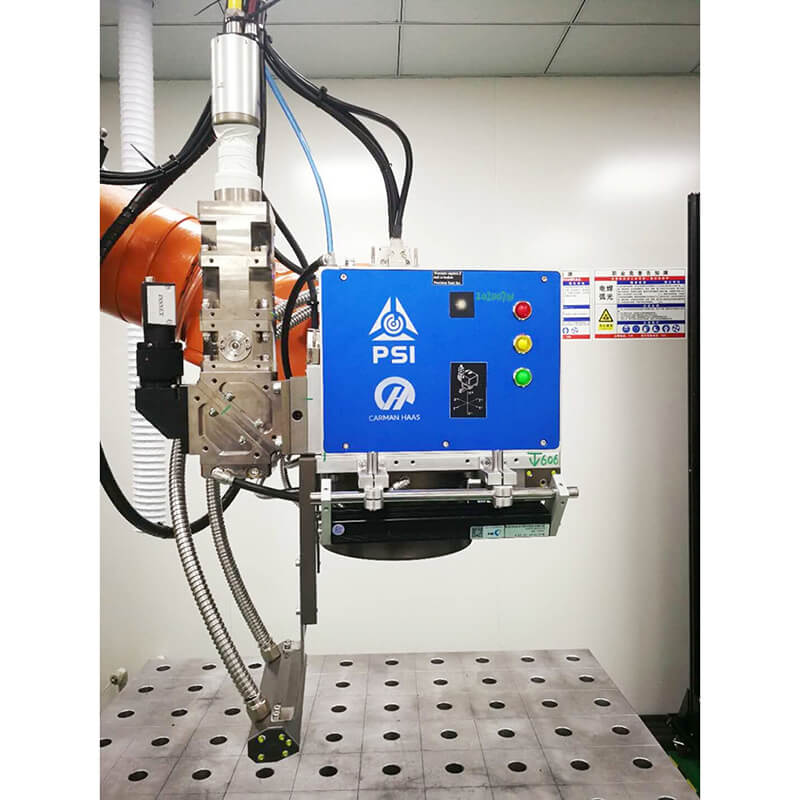

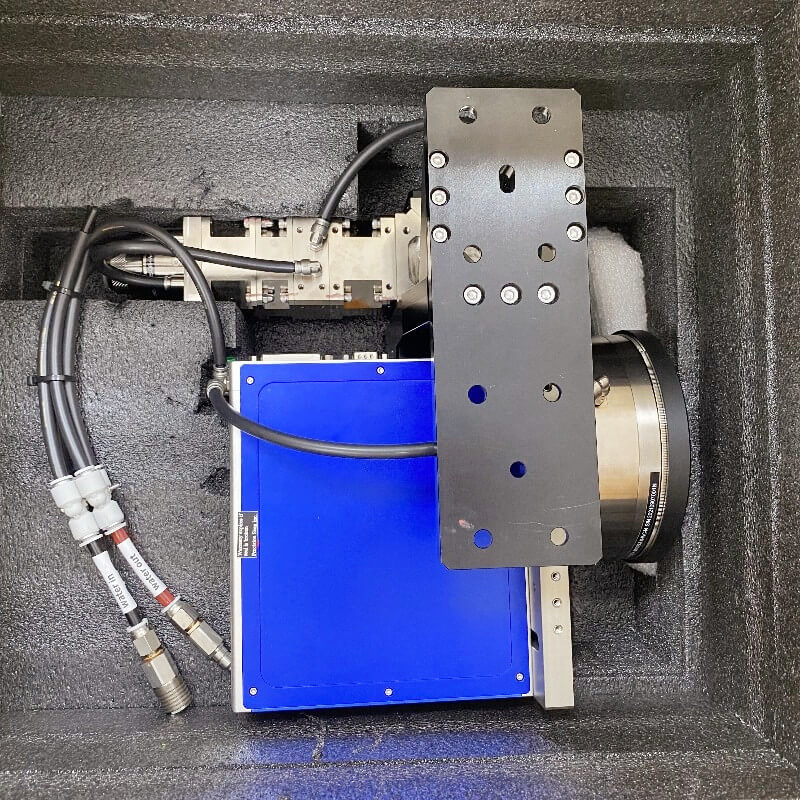

With its high-quality, powerful optical elements and our customized welding Software, CARMANHAAS hairpin welding system is available for the 6kW Multimode laser and 8kW Ring laser, working Area could be 180*180mm. Easily processes tasks requiring monitoring sensor can also be provided on request. Welding immediately after taking pictures, no servo motion mechanism, low production cycle.

1、For the hairpin stator laser welding industry, Carman Haas can provide one-stop solution;

2、Self-developed welding control system can provide different models of lasers on the market to facilitate customers’ subsequent upgrades and transformations;

3、For the stator laser welding industry, we have established a dedicated R&D team with rich experience in mass production.

1. Wavelength: 1030~1090nm;

2. Laser Power:6000W or 8000W;

3. Focus range:±3mm collimating lens moving;

4. Connector QBH;

5. Air knife;

6. Control system XY2-100;

7. Gross Weight: 18kg.